One of the main parts in cars is “Fuel Pump” or “Fuel Pump”. The gas pump is responsible for delivering gasoline from the tank to the car engine. It is obvious that if the gas pump does not deliver gasoline to the car engine properly and the ignition process is not done well, the performance of the car will be disturbed.

It is interesting to know that this pump directs gasoline to the car engine with a pressure between 2 and 6 bar. If this pressure is lower or higher than the standard value, the car engine will not work properly and other parts in the gasoline path will be damaged.

Therefore, it is very necessary and necessary that this part does its job properly and pumps gasoline to the engine with a suitable pressure.

In this article, we are going to examine how the gas pump works and tell you everything you need to know about this part. Stay with us.

Gas station components

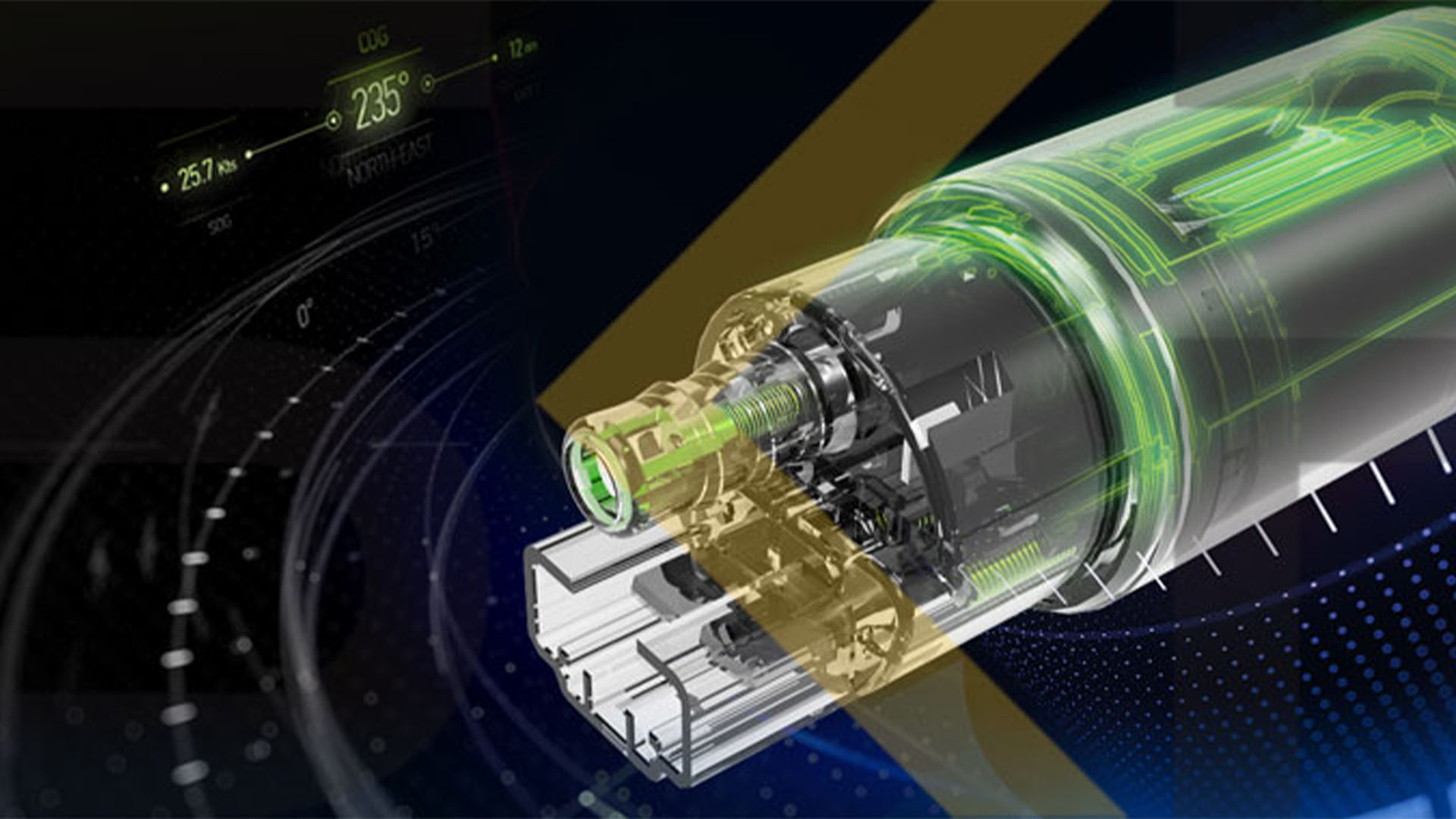

Gas station consists of different components, each of which has different tasks:

- Fuel filter

- Pressure regulator

- Pump support plate

- Fuel return pipe

- Fuel outlet pipe

- Fuel return pipe from the regulator

- Pump electrical current connection socket

- Return hose pipe

- Outlet pipe hose

- The degree inside the tank or the fuel gauge and spring

The location of the gas station

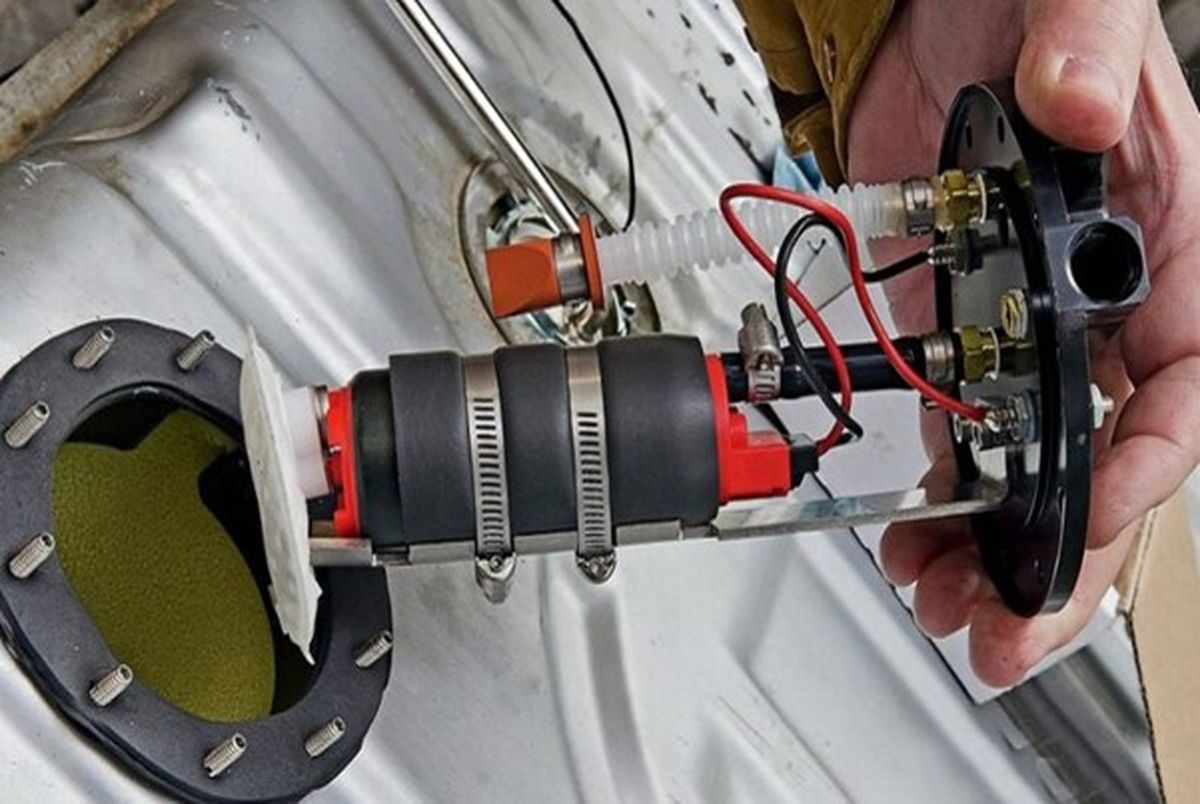

The gas pump is often installed inside the tank, although sometimes it is seen that this part is installed outside the tank in some cars.

Also, some cars are composed of two gas pumps in such a way that one of them is responsible for supplying fuel and the other gas pump supplies the pressure required by the injectors. The way the gas pump works causes heat to be generated in it, and this has caused some car manufacturers to put this part in the car tank.

The reason for this placement is the contact of the gas pump with the fuel inside the tank and its temperature decrease. Also, placing the pump inside the fuel tank makes the sound of the pump disappear during operation and does not enter the cabin.

Types of gas stations

“Types of gas stations” are generally divided into the following two categories:

- electric gas pump

- Mechanical gas pump

Electric gas pump

Electric fuel pumps that work when the switch is opened act like a sucker. The operation of this type of gas pumps is such that by sending a command from the ECU and the double relay, the fuel is sucked into the pump through the electric motor and by passing through the sides of the coil and the rotor inside the pump assembly, which together act as an engine. They are electric, they are cooled and sent to the engine.

Electric pumps are more useful compared to mechanical pumps, among the reasons why these pumps are widely used, the following can be mentioned:

- Electric pumps can be installed away from the engine body because heat does not affect it and gas lock (fluid vapors prevent liquid fluid from reaching the pump) does not occur in the pump.

- Electric fuel pumps deliver fuel to the engine as soon as the ignition switch is turned on. While mechanical gas pumps must first be turned on through the start key in order to start fueling.

- In electric gasoline pumps that are of the turbine type, due to the pressure of the gasoline transmission pipes, the tendency for gas lock and fuel evaporation in the pipes has reached the lowest possible level.

- In this type of gas station, two or more electric pumps can be placed in the fuel supply circuit so that if one of the pumps has a problem, the other pump can perform the task of sending fuel.

Mechanical gas pump

Mechanical gas pumps have nothing in common with electric gas pumps and have a lever called Shaitanak. This lever is stimulated through the valve shaft and starts to move. There are cams in this type of gas stations that are placed to hit the devil and with each blow that hits the devil, the devil goes up and down and acts like a pump.

When the devil’s head goes up, its end part goes down and causes the diaphragm to pull down. The vacuum created in the gas pump chamber causes suction and gas enters the pump.

This gasoline enters the pump through a one-way valve that only allows gasoline to enter the pump. A strong spring is placed under the diaphragm, which is responsible for returning the diaphragm to its original position and lowering the devil’s head. In this way, the gasoline entered into the pump is sent from the pump to the engine through another valve that works opposite to the first valve. This process is repeated with each rotation of the valve shaft, so that there is enough gasoline for combustion on a permanent basis.

Important points regarding gas stations

Due to the continuous use of electric current, electric gas pumps heat up and produce high heat, which increases the resistance of their coils and eventually burns and stops the pump. One of the points that must be paid attention to is to never let the gasoline in the tank be completely drained.

Because gasoline has a low temperature and is cold most of the time, when the pump is inside the tank, it is cooled by the cold gasoline and the possibility of burning is reduced.

If the gasoline in the tank is completely drained or its level reaches below the pump strainer, it will cause the pump to heat up and eventually burn. Also, the presence of water in gasoline causes the diaphragm or pump vanes to rust and seize. Also, it is necessary to check the strainer connected to the pump core, because if this strainer is clogged with garbage, a lot of pressure will be applied to the pump and the possibility of its failure will increase.

The operating time of the gas station

A specific life span cannot be considered for the gas pump, most of the time it is observed that the gas pump works properly and without any problems in the vehicle permanently. Many people replace the fuel pump or the fuel pump before any problem occurs, while this is a mistake because when the pump does not show any signs of failure, there is no need to replace it.

Signs of fuel pump failure

- The whiz sound of the gas station

- Hard to start the car

- engine jump

- Stalling the car at high temperature

- Gas without acceleration

- Not enough power in the engine